Generally suspension pivots come loose because they weren’t correctly bonded at the factory or there has been corrosion to one of the components which degraded the bond until it failed.

Modern suspension bikes generally either use a carbon-to-carbon suspension pivot, or an aluminium-to-carbon insert and in either case we can fix them.

Case study: Intense with loose carbon pivot

On this Intense you can see a carbon tube running inside the carbon frame which supports the suspension pivot. All the bearings in this design are housed in the linkage. In this case the carbon tube detached from the frame but we were able to repair it.

The white circle around the pivot is our fresh glue bond.

The glue we use is a special aerospace epoxy which isn’t available in New Zealand. It’s kinda like Araldite but about 10x stronger and 10x more expensive and is the same stuff Lockheed Martin use to hold the wings on fighter planes.

We use a tiny endoscopic camera to look inside the frame after bonding and check our work. Here we can see glue all the way around the pivot – this means we’ve got a full glue bond and this pivot won’t come loose again.

Case study: Specialzied with worn-out carbon pivot

This Specalized was been ridden with a worn-out set of bearings and the aluminium pivot bolt had ovalised the carbon frame. In this case we machined a custom aluminium insert and bonded it into the frame to make it better than new.

Like the Intense the bearings are housed in the linkage. What probably happened to this frame is the bearings seized and caused the pivot axle to rotate in the frame rather than in the bearing. The pivot axle soon wore through the soft carbon frame.

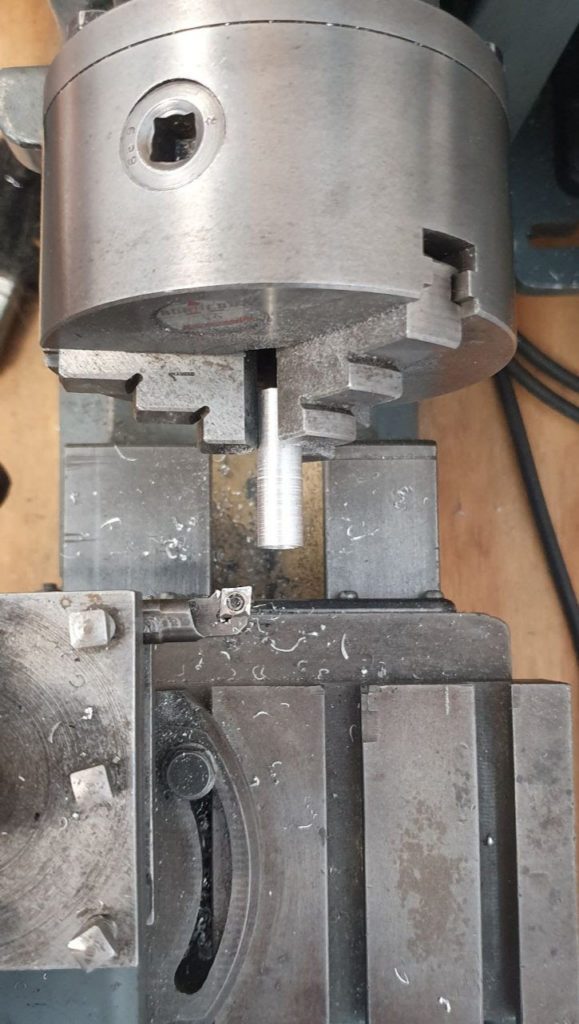

Custom aluminium insert being machined on the lathe. Having a lathe allows us to do all sorts of work in-house. In this case we debated making a carbon insert but because of the tiny size of this pivot decided that a hardened aluminium insert would be more durable.

Aluminium insert bonded into the carbon Specialized. You can see the consistent circle of glue around the insert showing that we’ve got a full and correct bond. This insert will last.

Case study: Turner with loose aluminium pivot

This Turner uses aluminium inserts which are bonded into the carbon frame. These aluminium inserts house the bearings. In this case we were able to re-use the old inserts once all the residual glue was cleaned away.

Dave Turner, the founder of the brand, consulted on how to best repair this frame so the customer wouldn’t be faced with a massive shipping bill and delay to send the frame to the USA headquarters for repair.

Alignment is Critical

The hardest thing with suspension pivots is ensuring frame alignment. If the suspension insert or pivot isn’t bonded correctly then suspension performance will be compromised, the frame won’t track straight, and it will chew through bearings. We’re able to ensure all suspension pivots are bonded correctly and usually to better tolerance than when the frame was new. I knew those years studying mechanical engineering would come in handy 🙂

Guaranteed work

We stand behind all our repairs 100%. You can have full confidence that we’ll correctly fix your frame.